UN1500 BC Enhancement of the Compatibility of PC and ABS

- Donna Chen

- Nov 20, 2020

- 2 min read

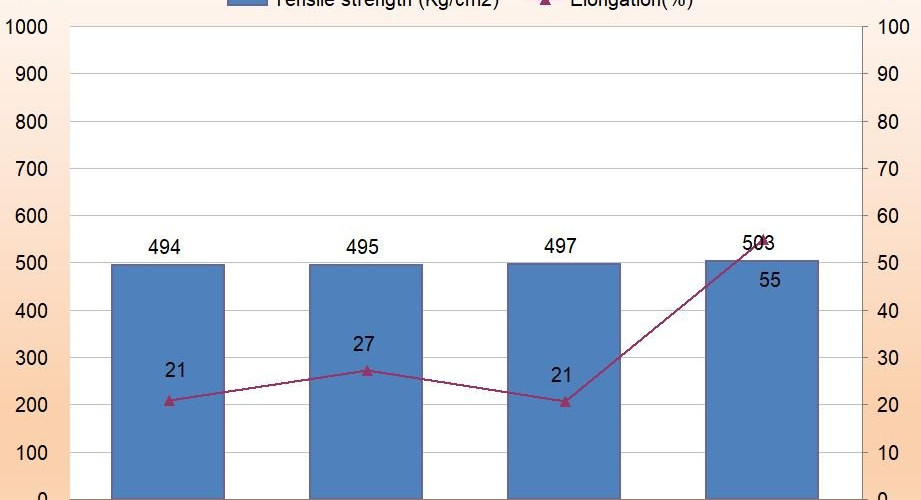

1. Experimental and Objectives1.1. To granulate with a twin-screw granulator the poorly compatible PC and ABS into PC/ABS blend. Thereafter, standard test pieces were produced using a 150-ton horizontal motor in order to examine its mechanical performance such as tensile, bending strength and impact resistance. 1.2. This investigation aimed to evaluate whether 1500BC-PP can be used as a surface active agent (surfactant) to improve the compatibility between PC and ABS, which are usually badly compatible with each other, with a further objective to largely improve the mechanical properties of the PC/ABS blend. 2. Results and Discussion2.1. The performance of PC/ABS blend is determined by the compatibility of the 2 constituent polymeric materials. If well-compatible, the physical and mechanical performances of PC/ABS will lie between PC and ABS. If badly-compatible, PC/ABS will have mostly lower physical and mechanical performances than PC and ABS. The function of the surface active agent is to enhance the compatibility between PC and ABS. Adding 1500BC-PP, the mechanical properties of the blend of PC and ABS can be largely elevated, meaning that 1500BC-PP can serve as the surface active agent to blend PC and ABS. 2.2. The increased addition of 1500BC-PP has led to significant increases of the elongation rate and impact strength of PC/ABS blend. The impact strength of commercially available PC/ABS is usually 35~55 kg-cm/cm.2.3. The tensile strength, bending strength and bending elasticity of PC/ABS varied little or slightly increased with increasing addition of 1500BC-PP

3. Conclusion

According to the experimental results, the mechanical properties such as tensile strength, bending strength and impact strength increased with the increased amount of 1500BC-PP added. Therefore, 1500BC-PP can be truly used as an surface active agent to improve the compatibility between PC and ABS.

Comments